Below is a summary of the interview with Mr. Zhou Jishou, a brick factory worker, recalling his time at the brick kiln factory:

► Daily Routine at the Brick Kiln Yard

During high school, Mr. Zhou used to work at the brick factory during summer and winter vacations to earn extra money for his family. The factory operated on a three-shift system: from 8:00 am to 12:00 pm in the morning, with a break in between, then starting again at 1:00 pm in the afternoon. The end time varied depending on the day's workload, and overtime could extend from 6:00 pm to 7:00 pm.

Working in brick production used to be a very popular job! Even people from the central and southern parts of Taiwan would come to the north to work as brickmakers.

.jpg)

► Weather-Dependent Work

Weather plays a crucial role in the brick-making process because the drying process is essential for the strength of the bricks. Even when the weather is good, workers cannot sleep well at night because they need to be alert to changes in the weather. On rainy days, overtime work is necessary to cover the bricks with waterproof fabric to ensure their strength. Sufficient space and ventilation are required during the drying process to ensure proper drying.

.png)

.png)

► Meager Wages

Brickyard workers use sledgehammers to break red soil to make bricks. Children are responsible for pushing the soil embryos to dry, then after drying, they use heavy-duty carts to push the soil embryos to the brick kiln for firing. Workers in the firing department put the red soil into a bulldozer, which turns the red soil into bricks. It may seem easy, but it's actually heavy and physically demanding. Workers work hard all day to earn about 23 New Taiwan Dollars per day, which is barely enough to afford a bowl of noodles.

► Anecdotes of Brick Firing

Brick-firing masters need good skills for the bricks to be aesthetically pleasing; otherwise, the whole batch may be ruined. However, during lunchtime, some workers eat meat to replenish their strength, then casually throw the bones into the chimney of the brick kiln. This is like adding fuel to the fire, causing the temperature of the kiln to become too hot, resulting in fragile and deteriorated bricks. The responsible worker would then be reprimanded.

.jpg)

► Child Labor

In the brick kiln, it was common to see child laborers, regardless of gender. Despite their hard work, they earned very little. Children were only allowed to help push carts filled with heavy red clay to the brick kiln. Sometimes, due to their lack of strength, they needed two children—one to pull and one to push—to move heavier bricks.

.jpg)

► Pleasing the Construction Companies

In 1975, there were 31 brick kilns in Linkou. These kilns sold their red bricks to construction companies, and each brick was sold for 1 New Taiwan Dollar. The survival of a kiln depended on the purchasing decisions of these construction companies, and most of Linkou's kilns had clients mainly in the areas of Banqiao, Xinzhuang, and Sanchong.

However, Uncle Zhou didn't particularly appreciate the bosses of these construction companies. Whenever they visited, they displayed a haughty attitude. To secure brick sales, supervisors and employees in the kiln had no choice but to address the bosses as "big brother." If they didn't flatter them, the bosses might refuse to cooperate with them and instead find another kiln to do business with. This could lead to the closure of our kiln. Such hierarchical relationships were quite pragmatic.

► Division of Labor in the Brick Kiln Factory

In 1975, there were 31 brick kilns in Linkou. These kilns sold their red bricks to construction companies, and each brick was sold for 1 New Taiwan Dollar. The survival of a kiln depended on the purchasing decisions of these construction companies, and most of Linkou's kilns had clients mainly in the areas of Banqiao, Xinzhuang, and Sanchong.

However, Uncle Zhou didn't particularly appreciate the bosses of these construction companies. Whenever they visited, they displayed a haughty attitude. To secure brick sales, supervisors and employees in the kiln had no choice but to address the bosses as "big brother." If they didn't flatter them, the bosses might refuse to cooperate with them and instead find another kiln to do business with. This could lead to the closure of our kiln. Such hierarchical relationships were quite pragmatic.

- Soil Extraction (Digging Soil)

- Administrative Department (Marketing)

- Accounting Department (Financial Management)

- Brick Firing Department (Firing Red Bricks)

- Transportation Department (Transporting Red Bricks)

► The Charm of Red Bricks

In the past, red bricks were not only used for building houses but also for interior partitions, and even sidewalks were constructed using smaller-sized red bricks, albeit with a different appearance. Wealthy individuals would use red bricks to build their homes, while poorer people could only afford to build with unburnt soil blocks, which posed a significant waterproofing issue. Additionally, there were doubts about the seismic resistance of red bricks initially. It wasn't until after the 921 earthquake that many red brick houses were found to be more stable than reinforced concrete buildings, leading to a greater appreciation for the seismic resistance of red bricks. Unfortunately, as red brick houses gradually transitioned to reinforced concrete, the industry began to lose confidence in the future of red bricks.

.jpg)

► Leisure Time at Work

During their breaks from work, workers often engaged in various activities to pass the time and relax. Some would gather around to chat and share stories, while others might play simple games or cards. Occasionally, workers would bring musical instruments such as guitars or harmonicas to the factory and enjoy impromptu jam sessions together. These moments of camaraderie helped to foster a sense of community and solidarity among the workers, making the factory a more enjoyable and lively place to be.

.jpg)

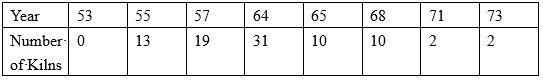

► The Era of Brickmaking Ascendancy and Tea's Decline

During that time, brick factories in the northern region gradually shifted from Neihu to Linkou, directly boosting Linkou's economy. However, the waste emissions from brickmaking caused tea gardens and acacia trees to wither, indirectly affecting the livelihoods of tea farmers and the quality of life of local residents. In 1964, Xinguang Brick Factory was established, which was the most famous brick factory during its heyday. It could produce 1.2 million bricks per month, with the thinnest red bricks being 4 inches thick.

.jpg)

► Traditional Brickmaking Process:

- Excavation: Red soil is transported to the brick factory using carts.

- Compression: Manual cutting and molding are used to form clay into bricks.

- Children pull carts to an open area to dry the clay bricks.

- Dried clay bricks are brought back to the brick factory.

- A certain quantity of bricks is stacked in batches.

- Firing: Bagua Kilns are used to fire the bricks at temperatures ranging from 1000 to 2000 degrees Celsius. (As there are many kilns, they rotate their usage to ensure quality.)

- Cooling

- Distribution to various locations: Builders in XinZhuang, Banqiao, and Sanchong.

.jpg)