► Qing Dynasty Period - Introduction of Tile Kiln Firing Technology

During the Qing Dynasty in the history of Taiwan, most master craftsmen migrated from mainland China to Taiwan. Moreover, transporting bricks and tiles to Taiwan was not difficult, so it became common practice to use mainland-made bricks and tiles. This limited the initial development of Taiwan's tile kiln industry. It wasn't until the mid-Qing Dynasty when a large number of Han Chinese migrated to Taiwan, bringing with them the tile kiln firing technology from the southern Fujian region. As a result, many government offices, temples, and luxurious mansions gradually began using red bricks and tiles fired in Taiwan. However, at that time, there were no dedicated kilns for producing red bricks. In traditional tile kiln production, red bricks were considered secondary products because they required a large amount of clay, were heavier and denser, and were very expensive, making them unaffordable for most rural households.

.jpg)

► Japanese Colonial Period - Onset of Industrialization: The Japanese introduced

the "Toun" kiln, primarily for firing pottery and bricks, marking a milestone in the segmented firing of bricks and tiles. They also introduced the "Bagua" kiln (aka Hoffmann kiln) , specializing in brick production, thus propelling the brick kiln industry into the era of industrialization.

1. Toun Kiln:

Mostly built on hillsides or on flat land with the land filled into slopes, the kiln body is constructed on the slope. The Toun kiln consists of interconnected kiln chambers, each rising like a staircase, hence its name "Toun" which means "ascending kiln". Each kiln chamber is independent and separate, allowing loading, firing, and unloading to occur simultaneously, making it a type of "semi-continuous" kiln. Its main feature is that loading, firing, and unloading operations are carried out together, saving time and fuel, and suitable for mass production.

The flame of the Toun kiln belongs to the "semi-updraft" type. The slow temperature rise of a semi-updraft kiln ensures stable firing, and by effectively controlling the temperature rise rate through chimney and flue structure, it perfectly meets the requirement of slow temperature rise in brick and tile firing process, resulting in consistent kiln temperature control and more uniform product quality. Hence, the traditional semi-updraft kiln became the main kiln type for brick and tile firing in the future.

.jpg)

.jpg)

2. Bagua Kiln:

The kiln occupies a considerable area, with a cylindrical outer shape, resembling the pattern of Bagua when viewed from above, hence the name. The kiln chamber is hollow and elongated, forming a circular arrangement when connected end to end. There are eight kiln doors along the long sides, with one kiln door each at the front and back ends, divided into three sections: the first section is for coal firing, the second section is for arranging brick blanks ready for firing, and the third section is for the fired bricks.

Additionally, the Bagua kiln uses coal as fuel. During firing, coal is sprinkled from above, requiring no electricity, gasoline, thus saving energy. One of its significant features is the ability to load clay while firing and simultaneously segregating sections, allowing continuous loading and unloading throughout the year. However, its development time was short-lived as it was quickly replaced by the automatic kiln known as the "tunnel kiln."

.jpg)

.jpg)

► The Rise of Red Bricks and the Decline of Tea Picking

After 1895, purchasing bricks and tiles from the mainland became less convenient. Coupled with the demand for public construction and urban planning, which required the introduction of new kiln technologies to produce red bricks locally, manufacturing and trading gradually shifted to Taiwan. As a result, Taiwan's brick and tile industry began to flourish. In the 1960s, during the peak of the construction industry, there was a high demand for Linkou's red bricks in the Taipei Basin. This led to the construction of numerous brick factories, with towering chimneys dotting the landscape and emitting smoke from brick kilns, creating a unique scene across the island. At its peak, there were as many as 34 brick factories in Linkou, with many brick kilns located along the eastern transportation routes for easy brick transportation.

The proliferation of brick factories in Linkou inadvertently provided a significant number of employment opportunities. At that time, brick factories were often adjacent to tea plantations. Therefore, local villagers engaged in tea cultivation found themselves working in the brick factories during most of their spare time, aside from the harvesting seasons of spring, summer, and autumn, as well as routine tasks like weeding and fertilizing. Additionally, with rising wages and the inability of Linkou's tea industry to compete with the renowned Paochung tea and oolong tea from Shiding and Muzha, many tea farmers gradually transitioned to work in brick kilns. Consequently, the picturesque scenes of tea farmers singing songs while picking tea on the mountains gradually disappeared from the local landscape.

.jpg)

► The Decline of the Brick and Tile Industry

In 1965, the global oil crisis triggered an economic downturn, indirectly affecting construction costs and leading to the introduction of new architectural forms. Building materials gradually shifted towards cheaper options like reinforced concrete, reducing the demand for bricks. Between 1967 and 1968, the rise of tunnel kilns introduced a production method different from traditional methods. Raw materials were no longer limited to red clay, and production costs were lower compared to the Bagua kilns. Consequently, traditional brick kilns in Linkou declined. Additionally, with the opening of highways, transporting bricks became more affordable, further reducing costs. Non-traditional tunnel kilns could not compete with such lower costs. Furthermore, with the development of the new Linkou Township, many brick kiln factories were designated for specific land use or converted into roads. Owners were forced to relocate, leading to the rapid disappearance of brick kiln factories in Linkou. The brick and tile industry eventually became a sunset industry.

Through this historical development, we can observe the rise and fall of an industry, which can be attributed to the following reasons:

.png)

(1) Red bricks do not meet environmental standards:

a.Resource destruction: The main material for red bricks is clay. While clay is abundant, the process of excavating and molding it for brick production can lead to the destruction of arable land.

b. Air pollution: Clay, the raw material for red bricks, is a non-renewable resource. The firing process emits significant air pollutants.

(2) Replacement by new construction methods: The trend is shifting towards

using reinforced concrete for building construction, which is more environmentally friendly than red bricks. Cement bricks do not pollute the environment during the production process. Additionally, cement bricks have advantages such as good water absorption, freeze resistance, and high strength.

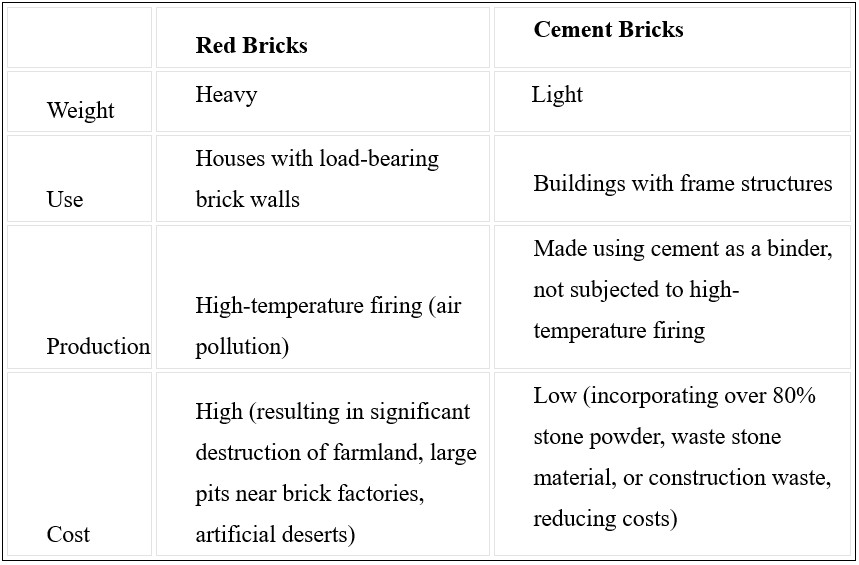

Comparison between Red Bricks and Cement Bricks

(3) Urbanization development: The development of the new Linkou Township has transformed former agricultural land into industrial zones, attracting a large population to build new residences and commercial buildings, thereby promoting local development and economy.

.png)

.jpg)

.jpg)