(1) Research Trajectory

| Date | Class Record |

| 09/15 | We used chromebook to write about: 1.What we know about Cyberfair 2.the audition process 3.What we want to learn this semeste 4.What we have prepared for Cyberfiair during this summer vacation |

| 09/22 | Club members shared their summer-investigation report respectively. Focusing on local

characteristics of Linkou, members submitted reports on various kind of themes. For example,

one member gave a report on Wufuyang Taiwan’s Socks Museum, another wrote about Prince

Creative Stationery Kingdom, and another studied a tea factory. In the end, we decided to

conduct a research on the face mask factory. We also tried to use mind map to design the

research framework.

|

| 09/29 | This time we brought up several questions and things we would like to know about Linkou face

mask factory. After discussing and classifying them, members divided into groups to gather

information, carrying out a more sophisticated research. During the lesson, the computer

teacher taught us to use Google keep in order to organize the data more quickly.

|

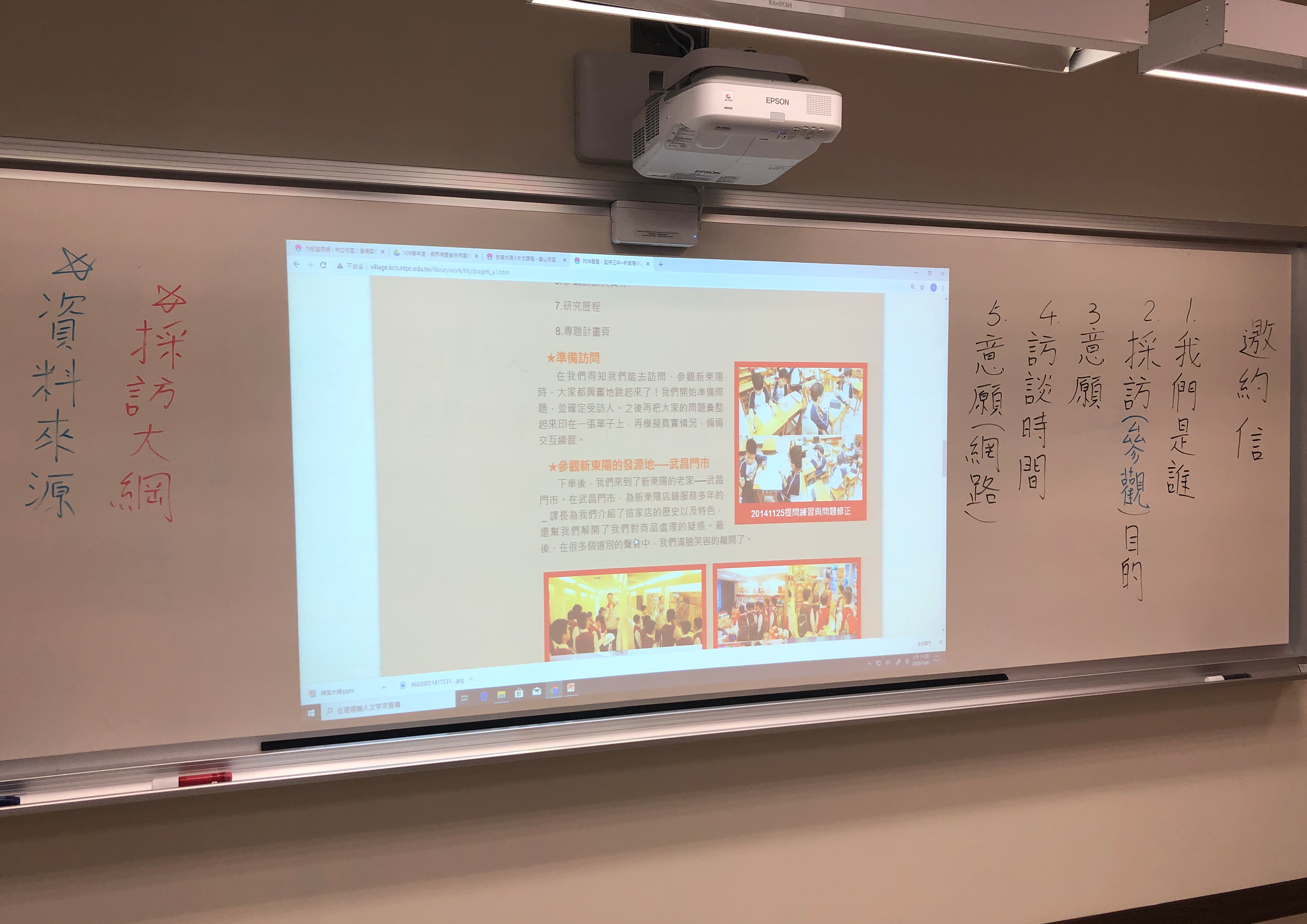

| 10/06 | We searched information about Welson Li Company. The teacher also taught us how to write an

interview-inviting letter.

|

| 10/13 | We finished collecting data and present it to all the club members. Students acquired information of diverse content, but it lacked of completeness. The teacher commented on the problems of each group, suggesting us doing more detailed data collecting and analysis. |

| 10/20 | We decided subjects of the interview and practiced formulating interviewing questions. |

| 10/27 | Students were divided into two groups, one made phone calls, and the other wrote a letter to invite the interviewee. |

| 11/03 | Conducting the interviewing training for the first time,we first practiced interviewing in

pairs at the classroom, then we went to the health center in school to practice interview,

recording the content in detail.

|

| 11/10 | We wrote survey questions for higher-grades students and modified influent sentences. |

| 11/17 | We prepared for the interview, conducted a stimulated one again, and studied the background

information of the chairman of that factory.

|

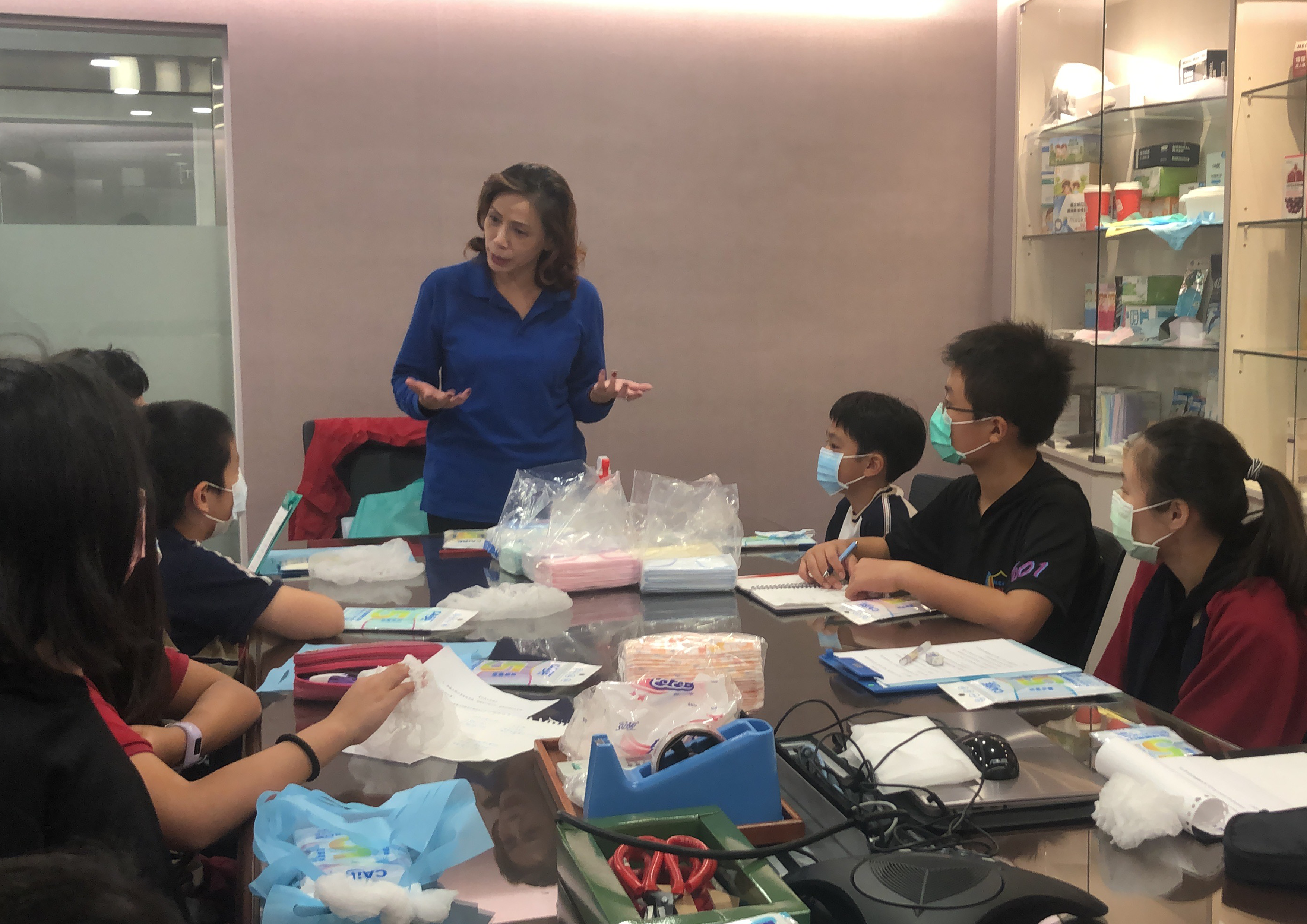

| 11/24 | Conducted the formal Interview outside the school. We visited Welson Li company, taking look

at various kind of face-mask-manufacturing machines, and asked chairman Chen some questions

personally. We were going to transcribe the interview in order to enrich the content of the

webpage.

|

| 12/01 | We made a document about the interview conducted on November 24. It recorded the questions and answers each person was responsible for, and other information about the market. Besides, every club member had to write a 250-words-visiting afterthought, which covered a wide range of topic, including visiting process, the afterthought of interview and other gain. |

| 12/08 | All the club members had to refine the transcript. Each draft had to be over 200 words. Each person took charge of 3-4 questions. Besides answering the question in detail, we also need to transcribe the interviewing video. We planned to translate the content into English next week. |

| 12/15 | Today, we translated our visiting afterthought and performed a statistics analysis on the survey data we collected. |

| 12/22 | Discussed the face mask video which was about to be put on the webpage and translate the content of the webpage. |

| 12/29 | Filmed the video and continued translating the content of the webpage. |

| 01/05 | Discussed the graphic design and typesetting of the webpage. |

| 01/12 | Decided the typesetting and proofread the content. |

(2) Visiting plan and the interview

- 1.Visiting procedure

| Procedure | detailed content | |

| Distributing the face masks according to the everyday quota set by the government | the government collaborates with the civil society, the number of the quota |

|

| Work division and operating of departments in the enterprise | research, marketing, accounting, special assistant, sales | |

| Viewing the face-mask-manufacturing process | Factory manager, workers, manufacturing equipment and production flow |

|

| The operation and management of the company | Chairman’s philosophy, crisis and opportunities of operation |

|

- 2.Outline of the interview

- (1)Through chairman’s previous interview, we know that the company has established at Linkou for 20

years. Could share the process of starting the business with us? During these 20 years, have the

company encounter any obstacle?

- (2)Besides the factory which manufacts face masks, what are the other departments in the company?

- (3)We saw “the operation philosophy of sustainable development, aiming at fulfilling different

levels of demand from various kind of customers” on the company’s webpage. Why do you uphold this

belief to run the company?

- (4)In the early days of Covid-19 outbreak, we saw that chairman provided face masks for the people

instantly. What was your thought at that time? Confronting the face-mask controlling policies of the

State, what were your company’s responses?

- (5)0 years ago, when SARS was in prevalence, was the company as busy as in the Covid-19 outbreak?

What’s the difference between the policies in these two periods?

- (1)There are many kinds of masks in the market, each has a different function. What types of face

mask do you produce?

- (2)What are the differences among the raw materials and manufacturing procedures of these face

masks? Are there any difference among the numbers of output?

- (3)When the epidemic broke out, the demand of face masks once exceeded the supply, how do you deploy

the products and human resources?Did you add more assembly lines? How many employees were required

for one assembly line? Are there any short of employees before and after the outbreak? Have you

recruit more people for the face mask factory?

- (4)Recently, face masks made in Taiwan have made a reputation internationally. How does the factory

control the quality of face masks in order to gain customers’ trust? Are there any plans to continue

enhancing the quality of products in the future?

- (5)When the epidemic broke out and the government requisitioned all the face masks, if you had

already collaborated with other manufacturers or planned to sell the products overseas, how did you

cooperate with the government or negotiate with other manufacturers?

- (6)The face mask has become the must have goods for tacking the pandemic around the country.

Comparing to the price before the outbreak, why did the price in Taiwan is more stable than that in

other countries?

- (7)Do you focus on producing face masks at the present stage? Or do you keep producing other

products?

(3) the conscience of the enterprise—chairman’s voice

Welson Li Company is an old enterprise, so we have many old costumers. Confronting the Covid-19 pandemic and cooperating with the requisition of centers of disease control, we have always stayed at work, providing the necessity for people. Recalling the time when the epidemic just broke out, we called back some colleagues at the beginning of 2020’s Chinese New Year. At that time, people were going to enjoy the vacation. But I knew that the epidemic broke, and there’s no time to wait. We received the call from ministry of economic affairs and the inquiry of the department of health. They were going to requisition face masks. So, without copping out, I ask factory leaders to request employees to manufacture the products together.

During the Chinese New Year vacation, we started to produce at a small scale, thinking that at least it will be better than nothing. Gradually, the face masks become as colorful as clothing. Taiwan has been through the challenge of the epidemic, the hardship of countering it, and the insecurity in lives. It is through the collaboration of all the people that we have made it. In this war, many anonymous heroes have contributed to Taiwan.

images:Philosophy of the enterprise-I CARE U

images:Philosophy of the enterprise-I CARE U

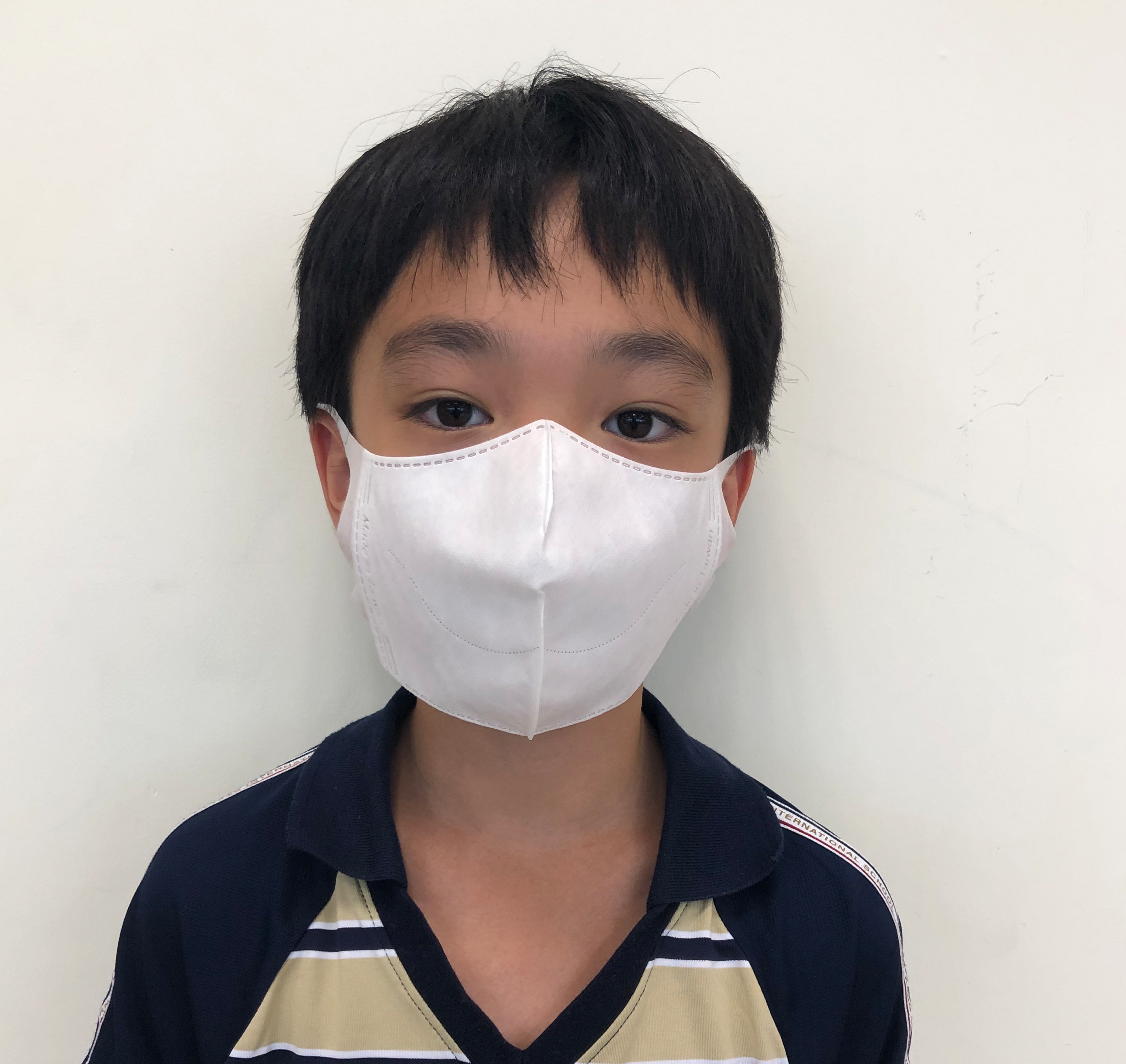

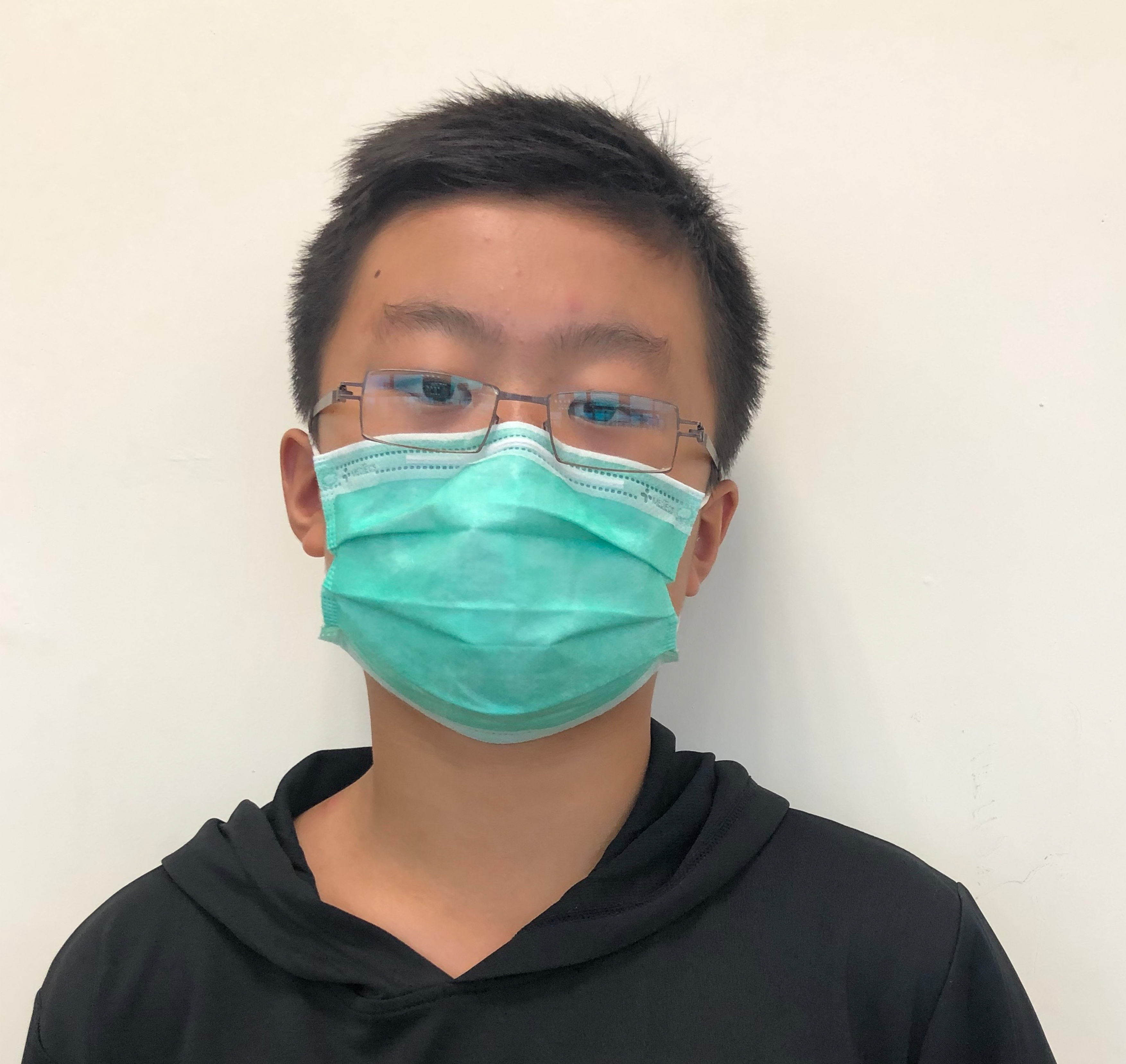

images:Photo of the interview

images:Photo of the interview

(4) Q&A –everyday life during the outbreak A

During the lengthy period countering the pandemic, face masks have become a necessity. People have also changed their habits and ways of living. The following is the knowledge related to hand cleaning and sanitizer that the school health center taught the students:

Q1: What is the difference between Milton and alcohol? Do they have any commonalities?

| Milton | Commonalities | Alcohol |

|

|

|

|

Q2: What is the difference between washing hands with water and using hand sanitizers?

| Washing hands with water | commonalities | Using hand sanitizers |

|

|

|

|

There are two types of hand sanitizers in the market. One is alcohol, the other is the one with some Milton in it. They share the same purpose. The difference lies in ingredients and functions. Milton is only preceded by Hypochlorous water, sanitizers with Milton in them are not suitable for hands since they can cause more harm on skin. Alcohol can be used to sterilize both objects and hands. There are many kinds of hand sanitizers in the market, some are added with other ingredients for fragrance and moisturizing.

(5) Survey

In this research, we discovered that there are various kind of face masks in the market, but only medical face masks can counter the pandemic. In order to understand elementary school students’ knowledge and conception on face mask, we used Google Forms to design 9 questions related to the topic. We gave the questionnaires to six-grade students. They were filled in by 130 people, with 30 incomplete ones. There are 100 valid questionnaires in total.

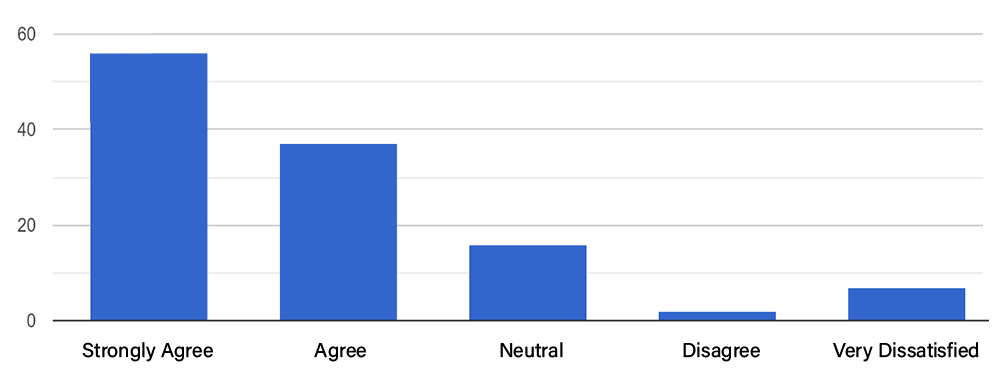

Q1: Do you approve the policy of receiving face masks in Taiwan?

Most higher-grade students are very satisfied with the policy, only a few people are not satisfied with it. It is probably because the policy enables people to acquire face masks quickly and conveniently, without facing problems like skyrocketing prices and mask stockpile. Everyone is entitled to wear a mask regardless their wealth.

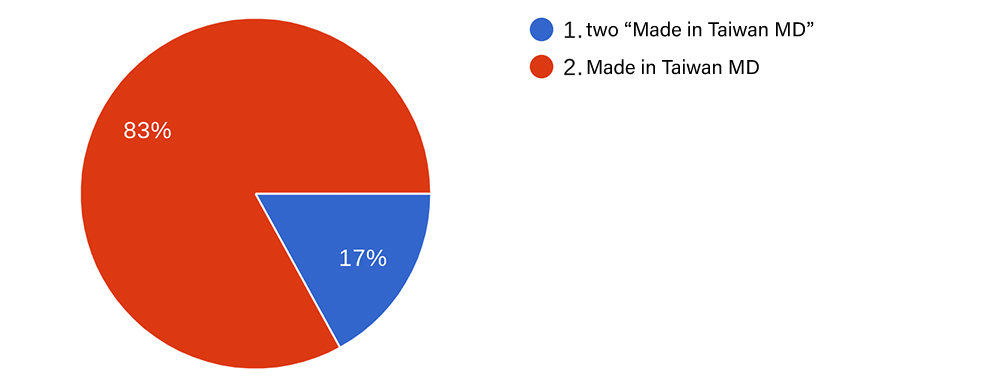

Q2:Which is the certification mark for face masks in Taiwan?

Most higher-grade students know that the certification mark for face masks in Taiwan is a transparent emboss “Made in Taiwan MD”. Only 17% of students think that there are two “Made in Taiwan MD” emboss on the mask. This result can probably be explained by the fact that many higher-grade students pay attention to the information released by the ministry of health and welfare. However, some people don’t. In addition, there are some illegal face masks in the market. So, there are still a minority of students who lack of the correct knowledge of identifying face masks.

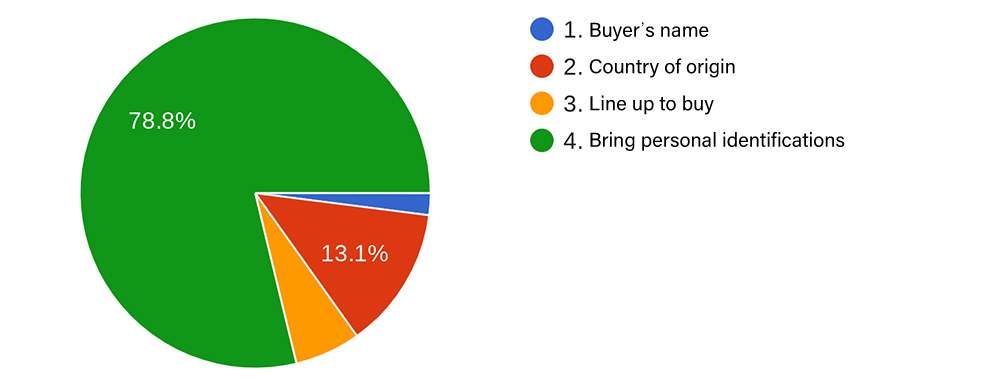

Q3. What is the meaning of the mask rationing plan?

78.8% of higher-grade students know that the mask rationing plan means that one has to bring personal identifications when purchasing face masks. Only 3.9% of higher-grade students consider that their names would appear on the mask. The majority of higher-grade students knows that when the mask rationing plan is implemented, one has to bring his National Health Insurance card. Those students who filled in the wrong answers may not pay attention. Or, it is possible that they never receive the face masks personally. Their families do the favor.

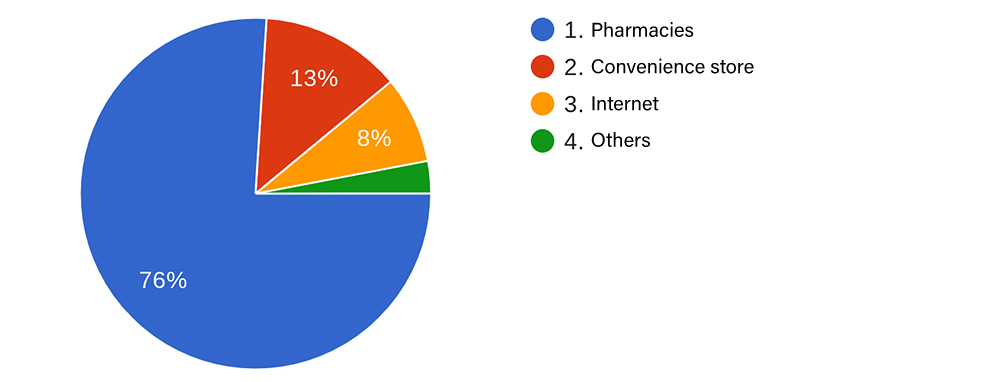

Q4. Where do you usually buy face masks?

76% higher-grade students go to pharmacies to buy face masks. Followed by 13% of students who go to convenience store, and 8% of them purchasing through internet. The reason that most people go to pharmacy is because that Taiwanese people generally consider the face masks supplied in pharmacies more secure, of higher quality and at fair price. For they have been controlled by the government.

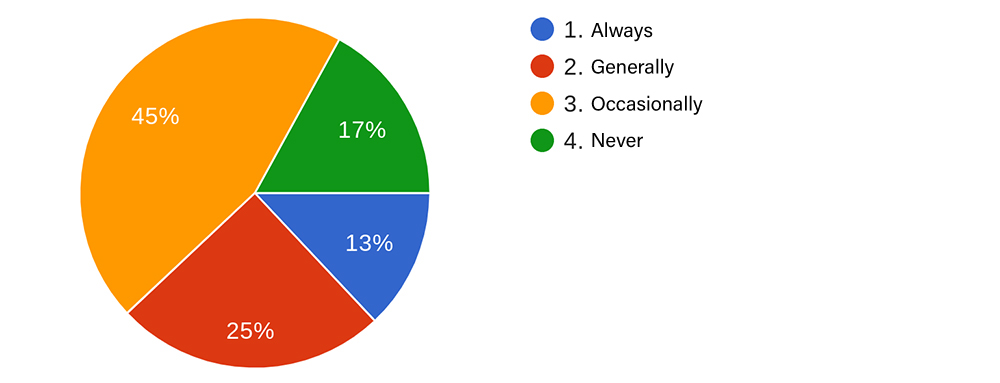

Q5. How often do you watch news about Covid-19?

This pie chart demonstrate that 62% of higher-grade students are not very concerned about the pandemic. They usually gain information from their teachers and parents. This shows that students in Taiwan should raise their awareness about public issues.

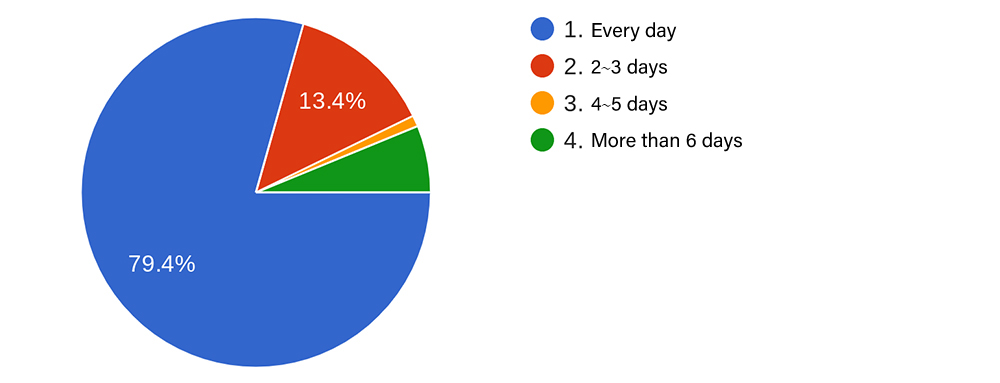

Q6. How often do you change face masks a week?

From the pie chart above, we can see that 79% of higher-grade students have correct notion about changing their face masks. Based on the research of ministry of health and welfare, if the mask gets dirty or wet, one must change it. One should not wear broken masks or wear the same one for over 8 hours. Thus, people should change it daily. In addition, to save face masks, one could wear a washable mask outside of the medical mask and clean it every day. This could also achieve the anti-bacteria effect. However, please note that the washable mask should be washed periodically, otherwise the medical mask would lose its protective function.

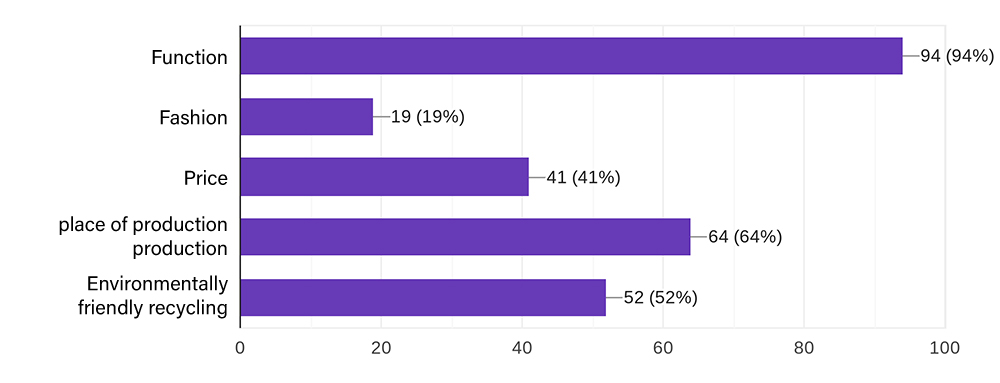

Q7. What are the things you consider when purchasing face masks? (choose 3 options at most)

The bar chart illustrates that although masks have gradually become part of the outfits, people still care about their practicality more than the aesthetics. 94% of students emphasizes the function of face masks, and 64% cares about the place of production. This shows that when purchasing masks, customers value function and quality the most. Furthermore, the discarded face masks are classified as unrecyclable “municipal solid waste”. As the quantity in use increases through time, the process of disposing used masks may increase the rate of indirect infection. To reuse face masks under the permission of contemporary technology and reducing environmental pollution have become the issue that major face mask manufactuers can think about.

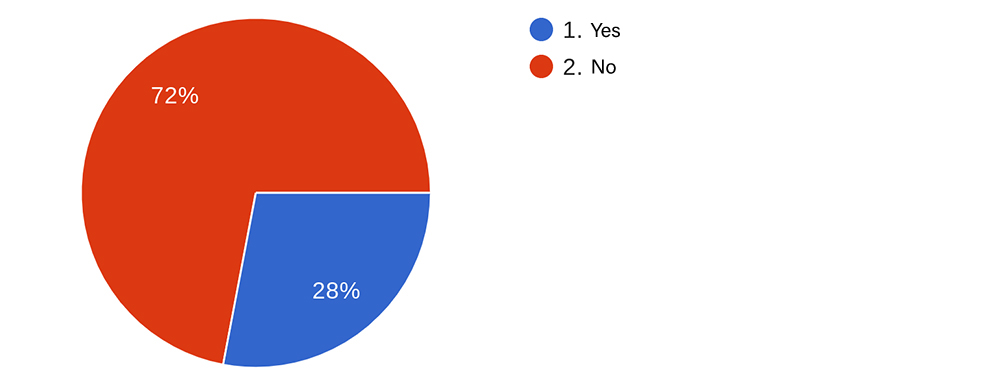

Q8. Do all the face masks in market have anti-bacteria function?

In this question, one can see that 28% of higher-grade students has incorrect knowledge regarding face masks. In fact, not all the face mask in market have anti-bacteria functions. When purchasing face masks, one has to identify the type of them to achieve protective effect. For example, there are cloth masks, N95, surgical masks, activated carbon masks and paper masks.

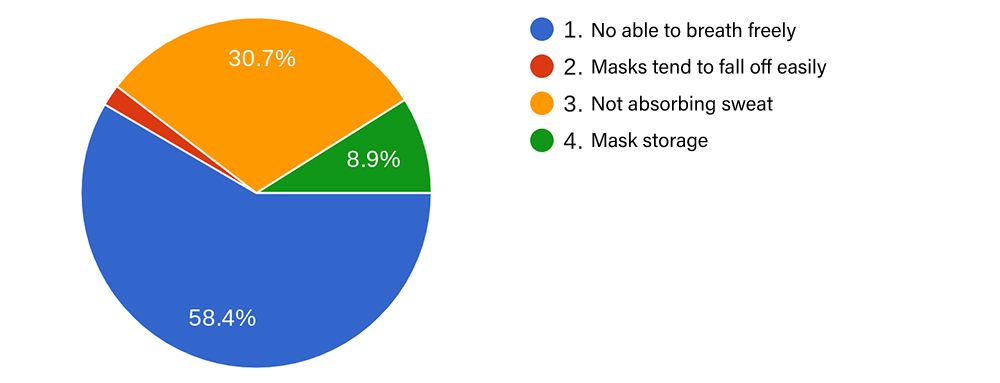

Q9. Are there any inconvenience when wearing face masks?

The pie chart about shows that 58.4% of higher-grade students consider “no able to breath freely” to be the major problem of wearing face masks, followed by 30.7% of students who regard “not absorbing sweat” as a problem of face masks. Only a few students consider that masks tend to fall off easily. Face mask factories can try to improve these problems in the future.

(6) Visiting Reflections

Ethan Xu 許浩晟

This was the first time I went out to visit a factory during club time. At first, we took a bus to Linkou Industrial Park, which is the location of the factory we were going to visit—Welson Li company.

Upon the arrival of the destination, I saw the trunk of a container car. The chairman told us this container car was going to distribute face masks to pharmacies and channels in all parts of the country. When we entered the factory, seeing four machines operating relentlessly, we were surprised that at least hundreds of thousands of face masks could be produced in a day.

Afterwards, the chairman showed us the procedure of manufacturing face masks. Before going in, we had to wear masks and sterilize our hands. The water repellent layer would be manufactured first, producing antibacterial layer is the second step , and finally the protection layer would be made.

After the visit, we interviewed the chairman. She shared the process of starting up the company with us, telling us that striving to fulfill various kinds of need of consumers is the philosophy that every enterprise needs to uphold. Thus, the non-woven fabric the company produced are not just the raw material of face masks. The factory also manufactures many related products, exporting them to Japan and sells them to various kinds of industries. For instance, tea bags, fruit bags, medical bandage and headgear. It is because of the epidemic that factory invests the main productive forces in face-mask production. To supply various kinds of products, the factory has to expand. This made us realize that the company relies on keeping up with the trend to thrive at Linkou for 20 years, without being eliminated.

Elaine Tsai 蔡沛妘

When entering Welson Li factory, we first took a look at the manufacturing process and packaging procedures of face masks. Then, we went to the office upstairs, listening to chairman’s introduction about masks and products made of non-woven fabrics. We also asked her a lot of questions, which informed us that during the outbreak of this pandemic, the civil society has collaborated with government. The factory donated masks, and the government gave productive machines back to them. This stabilized the demand of the market.

Chairman answered the questions carefully, I learned a lot about face masks from it. It takes many people’s collaboration to manufacture a mask, from processing, packaging to selling. One cannot complete it on his own. In addition, during the visiting process, I would like to thank all the employees who’s at the production front. I admire their carefulness and relentless effort of processing face masks. Their silent giving earned my gratitude.

Daphne Chen 陳思穎

After visiting Welson Li factory, I learned a lot about face masks and the application of non-woven fabrics. At first, we looked around the production line of face masks. The factory emphasizes hygiene, so we sanitized our hands and wore headgears before entering the shop floor.

Afterwards, the chairman and the plant manager introduced the assembly line to us. There are three kinds of fabric on the mask-making machine, also the nasal lines and the straps. The first layer of the mask is the water repellent layer, the second layer is melt-blown nonwovens, the layer closest to the skin is skin-friendly layer. 2-3 employees take the responsibility of packing in one assembly line. Every employee does a clean job. Very soon, a box of masks is finished. Because of the governmental requisition recently, the face mask factory has been producing masks constantly. The products are distributed to designated selling location by the post offices’ vehicles.

After looking around the production line, the chairman answered our questions one by one. I learned that to keep a company running takes a hard-working team, one cannot achieve it alone. It is this team which takes the company today, saving it from the declining traditional industry.

程渝心

We visited the face mask factory and saw Chairman Chen. Outside the mask factory, we took a group photo together. The chairman also told us that the company holds care as their philosophy. After that, we went to take a look at the inside of the face mask factory.

The first thing we see is a bunch of paper boxes, which contained face masks for the government and the ones that were about to be export under government’s approval. The first station we went is an assembly line of a relatively small scale. Every employee of the company takes care of different working spots. Some of them fix the machine, some are responsible for packaging, some takes the responsibility of checking. The manufacturing process is very meticulous. The products have to been through different examinations before selling.

The most impressive thing is that one of the machine is earned by exchanging millions of face masks with the government. The manufacturing process is harsh. The second spot is a larger production line. Factory employees care much about hygiene, before entering the factory they have to been through sterilizing measures, wearing hats and gloves. The plant manager explained knowledge about masks to us, such as the composition of masks, their raw materials etc. We also took a photo with the female workers.

During the interview, we listened to the chairman’s illustration of various products produced by the company, which includes microwaves and cosmetics. We also asked the chairman about her philosophy of operation. She them showed us the diverse masks the company made to keep up with the trend. They are of different colors and styles. She also introduced the happy cat mask which is about to go into the market to us.

Through this research, our team hopes to let more people understand the manufacturing process, quality management and types of face masks. It is only through correct knowledge that people can fight against the pandemic together.

Reina Chang 張立欣

In order to get to know about the production of face masks, we went to visit Welson Li company which is near the school. We learned a lot from this visit.

In the beginning, we saw a huge cargo trunk in front of the gate. The chairman told us this is the government’s car which serves the purpose of requisitioning masks. Afterwards, the chairman showed us around the assembly line. We wore headgear and sanitized our hands before entering. On entering the factory, we see workers counting the quantity of masks, packing them adeptly. Even with the presence of us, they didn’t stop their work. During the visit, I learned that these machines work relentlessly to make sure there are sufficient masks in Taiwan. This enables the export of face masks overseas and the reasonable price we enjoy.

Finishing looking around the factory, we went to the meeting room to conduct an interview. The chairman first introduced the types of masks made by the company, then demonstrated other products made of non-woven fabrics. Besides, we also tried the factory workers’ job, packing the masks and took them home. This visit of Welson Li company grant me knowledge that’s not on the internet. I learned a lot.

Ian Chang 張允安

We went to Welson Li company to interview the chairman. We all learned a lot about the types and knowledge of face masks.

On arriving Welson Li company, I saw a trunk of the post office which was going to requisition masks from this company. Before entering the Welson Li factory, we wore head gear and face masks, and sanitize our hands with alcohol. Upon entering the factory, we heard the sound of machine operating, seeing employees working carefully.

After looking around the factory, we went to the meeting room to conduct the interview. We asked many questions about face masks, which all received detailed answers from the chairman, who answered us patiently. What impressed me the most is that the chairman said as part of Taiwanese people, she has to contribute to Taiwan. At the beginning of the outbreak, she took the responsibility of enterprises, providing free masks for the people. Her acts are moving.

John Huang 黃品傑

Despite the fact that it’s my second time of attending the cyberfair club, I still brought an uneasy heart to Welson Li company to conduct the interview. Upon arriving the spot, we discovered a huge cargo trunk in front of the entrance. The chairman told us is for the masks. Now I get that masks are distributed like this every day!

At first, we went inside of the factory, seeing every employee working incessantly. Walking inside, the chairman invited us to the shop floor. Everyone had to sanitize their hands and wear hats before entering. All the employees were packing and checking the products adeptly. These workers and machines had been working relentlessly from March. Whenever the misfunction occurs, technologists would come to fix the problem, fearing that it may hinder the company’s production capacity. The chairman is a very interesting person. I think it is because this kind of working atmosphere that the employees can continue their hard work.

After visiting the shop floor, we went to the meeting room for the interview. Upon arrival, I was caught by various kinds of products on the window. They not only manufacture face masks, but also nonwoven bags provided in 7-11, tea bags and coffee bags. A company has to develop diversely to fulfill people’s need.

Violet Yang 楊紫涵

This visit impressed me. It informs me that there are many kinds of face masks. This is the first time that I visited a face mask factory. So, I was looking forward to the image of producing face masks.

Upon the arrival, the chairman showed us the manufacturing process of face masks. We saw the producing process and the production machines. We also learned the factory’s characteristics. There are hundreds of face mask factories in Taiwan, but only a few produce surgical masks, which accounts for 10% of all the face masks factories. In addition, the chairman introduced some products made of non-woven fabric to us. Tea bags, fruit bags and dusk bags are some examples. I learned that it takes constant innovation for a company to thrive at Linkou industrial park for over 10 years. Otherwise, it would be eliminated by the consumers.

Angel Tien 田翎

I’m happy to visit the face mask factory this time. During the visit, I learned some information about face masks and their distributing process. I owe my gratitude to Welson Li company which grants us the opportunity, and the workers who helped and explained to us. I learned a lot from them. Before visiting, I thought the cost of a mask is very low, so the price should be lower than 10 NTD. After the visit, I got to know that it takes a lot of human forces and production costs to make a mask.

There were only 7 production lines before the outbreak. The government gave them a new face mask manufacturing machine to protect people’s health and security. Adding another assembly line has both pros and cons. The benefit is enhancing the production capacity. The drawback is under the circumstance of lacking enough employees, the workers has to work overtime. We should use our face masks properly, cherishing the effort all walks of life made for the pandemic.

Angel Hsu 許芷妍

I was curious and exciting in this visiting experience. The chairman demonstrated the manufacturing process of masks and the work of different working spot in person. The thing that touched me the most is seeing workers making face masks carefully. To make a face mask, it is not enough to rely on machines, human forces are also required. The chairman of Welson Li company once said that they’re doing a conscient enterprise. Producing masks is not for earning a lot of money. Their priority is the health of the nationals. This kind of spirit of “taking from the society and giving back to it” deserves other enterprises’ follow.

Reference

- Ministry of Health and Welfare

- Welson Li Company

- Linkou Industrial Park Service Center, Ministry of Economic Affairs

- Mask classification tutorial

- Automatic face-mask-manufacturing machines

- Comparing the market price of face masks in different countries Figures made by Ministry of Economic Affair

- Folk tv news