► The manufacturing process of Long-Shou tea

The moisture content of leaves when picking from the tea tree is usually 80%. The manufacturing process can be divided into 8 steps. These steps aim to lower the moisture content in tea leaves to 5% and make the taste sweet and smooth.

1.Pick fresh tea leaves—Long-Shou tea

In the process of picking fresh tea leaves, it is required to notice the picking method and the growing condition of tea leaves to harvest tea of high quality. The equipment needs to be well-prepared. Fresh tea leaves are leaves just picked from tea trees.

the growing condition of tea leaves

When the terminal buds just sprout, they are too tender to be picked. It is only after the terminal buds has fully grown, and the leaves just opened, that the most suitable timing for picking comes. This is called the open of tea leaves.

picking method

When picking tea leaves from trees, first open you hand and make the sprout reach your purlicue. Your index finger has to touch the stem of tea leaves. After that, hold the nail of your thumb against the stem, and press it on the second part of your index finger. Press with force, and then clamp the stem between the index finger and the middle finger with your thumb. Leaves picked by this method is called “one tip, two leaves.”

One tip stands for the tea sprout just picked, and two leaves represent the two tender leaves under the sprout. Picking one tip and two leaves can make the taste balance, for the tea sprout taste bitter, stringent, without scent and has a sweet after taste, whereas the tea leaves taste sweet and aromatic yet has no sweet after taste.

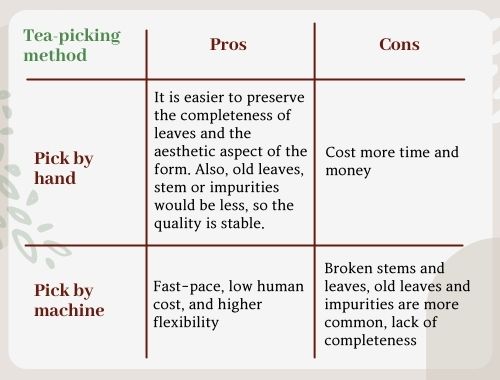

Besides picking by hand, picking with machine is also a common picking method in tea gardens at low altitude. When picking with hand, two people would move horizontally to harvest and pack them in a large nest. When picking by machine, the harvester would drive the machine to harvest automatically. These two tea-picking methods have pros and cons respectively, as shown in the table:

Tea-picking equipment

In the everyday lives of tea farmers, they wear bamboo hat, over sleeves with flower patterns and bamboo baskets when moving around in the tea gardens.

2.Withering

After picking, the leaves need to be irradiated by the sun in order to enable the fermenting process and get rid of the bitterness. The landform of Linkou is table land, causing the climate rainy, foggy and the air humid. As a result, local tea farmers classified the withering step into sun withering and indoor withering.

Sun withering

Spread tea leaves carefully with hand. Grabbing too tight would hinder the draining process of tea leaves. Expose the tea leaves to the sun. The duration is contingent to the intensity daylight. When the daylight is intense, the process could be finish in 5-10 minutes. With lower intensity, it would cause 20-40 minutes or replace by hot-air withering. When the tea leaves look 80% matte and smiles without the scent of grass, we could proceed to the next step. In the withering process, if the tea leaves turn into 100% matte, the quality would lose control due to the over-exposure.

Indoor withering

Stir and stand the leaves indoor. Stir the fresh tea leaves and stand it for a while. Repeat this step and put them into the tossing machine until they smile sweet. The whole process takes 8 hours. The purpose is to facilitate the fermentation of tea leaves to bring out the scent. Generally, tossing tea with hand needs to be conducted 2-3 times, and the farmers would also clean the impurities and old leaves among them. After that, using the tea tossing machine 1-2 times. Follow these steps make the quality of tea higher.

3.Stir fixation

Stir fixation is also called blanching. It is the process of eliminating the viability of the oxidation enzyme in the fresh tea leaves. At early years, tea farmers conduct this process through stirring in a pot heated by burning woods. Nowadays, they use tea-stirring machines to stir-fry the leaves at 270-300 degree for 8-9 minutes. During the process, they would check the degree of doneness with hand. After the process completed, the tea leaves would become soft and without the scent of grass.

4.Rolling

Rolling means to rub the tea leaves that have been through stir-fixation and force out the juice. This step shape them into a strip shape with a sticky touch. If the leaves are too dry, that means it is over stir-fixed; if the leaves are too sticky, it means they are not done. This step is generally done with tea rollers nowadays. The machine would first crumple the leaves and stem to reveal the flavor of tea and facilitate the rolling work afterwards. However, since the production amount of Linkou’s tea isn’t considerable, tea farmers here usually go through this step with hand in order to enhance the quality.

5.First drying

After the tea rolls are separated, the next step is the first drying of fresh tea leaves. It is the first drying process of tea leaves. Farmers would put tea leaves into the drying machine and dry them through shaking at several layers. They use hot air to dry the tea leaves until the surface is waterless, the moisture content is lower to 30-35%, and the touch of leaves become soft, flexible and not sticky. This step sets the flavor of tea preliminarily.

6.Cloth rolling

Use a tea cloth to wrap the dried tea leaves, wrap it tight with force until it becomes round and curly. Rolling, drying and cloth rolling are several steps that needs to be conducted repeatedly.

7.Roasting and drying

After cloth rolling, put the tea leaves in to the roasting machine to roast it, evaporating the moisture content that is useless, and bringing out the flavor of tea leaves.

8.Refining

Further select and classify to make the quality of tea higher.

1.screening: classify tea leaves based on their size

2.cutting: cut the leaves into the size you need

3.De-stemming: remove the stems

4.winnowing: blow away the fractures

5.Drying again